SHAW Sensor Technology

SHAW Aluminium Oxide Sensor Technology

The general operating principle of aluminium oxide sensors for measuring moisture in air and gases is well known. However, construction differs widely between manufacturers, and those differences are critical to real-world performance and reliability.

Some suppliers market their versions with terms such as “Hyper Thin Film Technology”, “ceramic” or “silicon” sensing (all essentially aluminium oxide on a substrate), or simply “thin film”. Ultimately, what matters is field stability and performance.

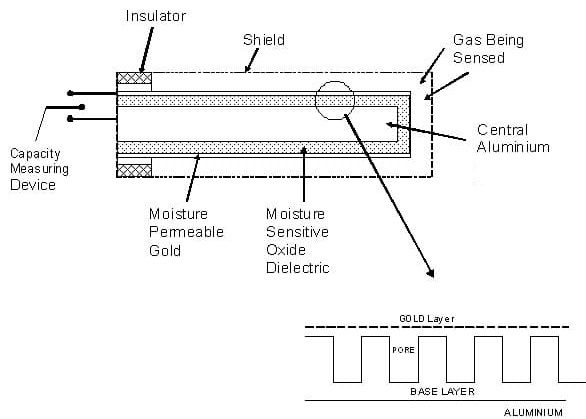

Shaw Moisture Meters sensor construction

SHAW dewpoint sensors offer three major advantages, all stemming from how the oxide layer is manufactured:

-

Selective response to water vapour

-

AutoCal

-

Freedom from low dew/frost-point drift

The sensor is built on a high-purity aluminium base. Its surface is chemically oxidised to create a pore-filled insulating layer of partially hydrated aluminium oxide. A porous, conductive gold film is deposited on top. The gold layer and aluminium base form the plates of a capacitor.

The oxide dielectric is a matrix of tubular pores running from the base insulating layer to the exposed surface. SHAW’s process precisely controls both this base layer and the pore dimensions.

Selective response to water vapour

Pore size is tightly controlled to be effectively specific to water vapour. In use, water molecules enter the pores. Their Brownian motion is restricted, promoting adsorption onto the pore walls. Because water has a very high dielectric constant, the adsorbed moisture produces a measurable change in capacitance. The quantity of adsorbed water corresponds directly to the moisture content of the surrounding gas.

Small-molecule gases such as hydrogen can enter the pores, but their dielectric constants are so low that their effect is negligible. Substances with high dielectric constants but larger molecules (e.g. methanol) cannot penetrate the pores and therefore do not influence the measurement.

AutoCal

The same pore-size control also enables control of pore capacity. That capacity sets the upper adsorption limit. During operation, the sensor settles to a dynamic equilibrium between ambient water vapour pressure and adsorbed water. By defining the overall capacity, SHAW defines the upper measurement limit. A sensor designed with an upper range of 0 °C dew point will saturate at that point and provide no further output as the dew point increases beyond it. This principle underpins AutoCal.

When using AutoCal, the actual humidity of the reference gas (ambient air or another humid source) is unimportant, provided it is wetter than the sensor’s capacity. The capacity is the “span” or wet end of the calibration. During AutoCal, you simply adjust the transmitter to read the span value (0 °C dew point), realigning the calibration curve closely with its original. This can be done whenever slight contamination is suspected. In cases of heavy contamination, factory recalibration or sensor replacement may be required.

Freedom from low dew/frost-point drift

While the primary pore size and form determine sensitivity and response speed, the quality of the base insulating layer sets the sensor’s base capacitance and long-term stability. Only a uniform, defect-free base layer yields a reliable, drift-free sensor.

If the base insulating layer contains pores or micro-cracks, these act as capillaries that slowly adsorb/desorb water. When exposed continuously to very dry conditions, such sensors can drift as these capillaries dry out, showing readings that appear drier than reality. In severe cases, the signal may drop below the lower calibration limit and the instrument will sit at its minimum dew/frost-point value.

Because this capillary layer dehydrates slowly, it also re-hydrates slowly, creating a “flat spot” where response to rising moisture at low dew/frost points is sluggish or absent. Aluminium oxide sensors using impedance-based circuits can show exaggerated drift from this effect, especially if capillary pores extend to the aluminium core, increasing resistive behaviour.

The SHAW sensor

Years of development have produced a SHAW sensor with a highly stable, uniform base insulating layer, eliminating dry-end drift and avoiding flat-spot response after prolonged dry-gas operation.

Primary pores govern speed and sensitivity. SHAW’s continuous R&D delivers uniform, water-vapour-specific pores that produce large, predictable capacitance changes with rapid response. The designed pore capacity enables the invaluable AutoCal feature, combining fast, selective measurement with robust long-term stability.

Visit the Shaw Moisture Meters (UK) Ltd website for more information on SHAW Sensor Technology