Heating Industrial Workplaces

18-05-2018

The Inside Track On Heating Industrial Workplaces

The temperature of heated industrial workplaces has a bearing on some aspects of health and safety, but also on productivity, the integrity of the building and indeed, whats inside it. It is not law, but it is widely recognised that workers perform best between 16°C and 24°C, depending on what kind of work is being done. Higher physical activity levels, i.e. manual labour, is performed best at lower temperatures and incurs less risk of heat related stress. Conversely office work and fine, dexterous work will require a slightly higher temperature.

According to the Chartered Institute of Building Services Engineers, (CIBSE) different working environments require differing temperatures. For example:

Heavy work in factories: 13°C

Light work in factories: 16°C

Hospital wards and retail: 18°C

Offices and dining rooms: 20°C

In addition to the obvious consequences of not enough heating, occasionally there are instances of badly specified, designed or poorly controlled heating resulting in overheating, where issues can include low levels of employee concentration, dizziness, fainting, or even heat stroke. This oddity can arise where the fabric of an old building has been upgraded to modern standards but the old and consequently over sized heating system retained. Apart from the social consequences, carbon footprint and energy costs will be far higher than required. Not only can this be attributed to the use of the wrong heaters, but also lack of proper heater control as well as poor ventilation and air circulation.

Types of Heating

Gas fired

Direct Gas Heaters

Direct gas heaters are useful for heating workplaces with large open spaces, such as warehouses and industrial site environments. To use mobile gas direct fired heaters, sufficient ventilation of the room is essential to prevent a deficiency in ambient oxygen levels, and to prevent humidity levels getting too high. Direct fired gas heaters have been traditionally used to heat workshops, warehouses, construction sites and foundries, and for many years have been the automatic choice of the hire industry.

Indirect Gas Heaters

These heaters have the added ability to dry buildings during construction, or after flooding, by pumping large volumes of warm, clean, dry air into the space without increasing the relative humidity of the workplace - indeed the %RH will fall as the temperature is increased. With all the convenience of easy mobility but without concerns about ventilation and oxygen supply, these mobile indirect gas heaters are a very versatile way of delivering larger volumes of hassle free heated air into marquees, building sites, industrial and agricultural buildings.

Fixed Gas Radiant Heating

Gas Plaque Heater

With remarkably fast warm up times gas plaque heaters are really useful for heating industrial workplaces. They tend to find their application in industrial buildings where the heating requirement is more 'occasional' than 'full time'. There are various small portable products up to about 36 kw which are fuelled from bottled gas, and also fixed plaque heaters which can run on natural gas. The nature of these heaters is that they create CO2 so as with direct fired heaters, there is a requirement to ensure that there is sufficient ventilation to ensure that there is no build up of CO2 and humid air.

Oil Fired Heaters

Indirect Oil Fired Heaters

vwigm_ec32-1 These are most commonly used in the marquee / event / temporary structure industry to provide clean, dry, thermostatically controlled heat inside the structure, with the heater standing safely outside. They are also widely used in construction, horticulture and agriculture and for general space heating.

The Arcotherm indirect heaters are a popular choice for marquee applications where it is important to control the temperature to a pleasant setting to ensure that guests are comfortable. Heaters such as halogen heaters, patio heaters, cabinet heaters, and table heaters are not suitable for the application as neither have internal fans, and in addition can pose a trip hazard due to trailing power cables. The Arcotherm heaters however, are placed outside and out of the way, leaving a clean aesthetic feel inside whilst providing warm, clean, dry air into the space.

Electric Heaters

Radiant Electric Heaters

Industrial radiant heaters are ideal for applications where rapid warm up times are required and open buildings require zone heating that would be impossible with space heating technologies. Smaller portable radiant heaters are available in both 230v and 110v, whilst for installed radiant heaters there is a choice of ceiling and wall mounted heaters. Electric radiant heaters are even available for mounting heights up to 20m - ideal for high bay loading areas and covered yards. However, the application is most suited to just heating specific work areas within a larger, relatively cold building. Radiant electric heaters also provide a rapid warm up time which can make them an ideal choice for buildings that get occasional use e.g. commumity halls.

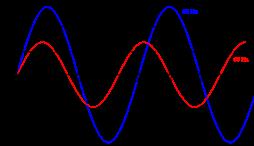

Electric radiant heaters find an ideal application in Hot Yoga studios. Radiant Heating for Hot Yoga places significant demands on a heating system because not only does the heating system need to be able to bring the temperature up to around 40°C. It also needs to be able to maintain that temperature within a relatively tight control band. The best heaters to meet the demands for temperature and of controllability are ceiling mounted electric radiant heaters. The Frico range includes a model called Elztrip which has the advantage of having a clean white finish, which suits a studio environment. Levels of controllability are enhanced with a control system where the power to the radiant heaters is rapidly pulsed on and off, and where the duration of the off and on parts of the cycle are altered to suit the temperature resulting in a much smoother temperature control especially when compared to a basic thermostat.

Electric Fan Heaters

Tiger fan heater

Industrial electric fan heaters bring the advantage of readily portable, easy 'plug and play' to heating industrial workplaces. There is a huge range of types and capacities. Some smaller ones are 230v or 110v, whilst larger ones are 415v 3 phase. Some are built to be ductable, allowing warm air to be directed to where it is need, possibly a drying process or into a room. Some are wall mountable and have variants that are designed for dusty environments or very wet or corrosive environments or for creating hot environments. But the overall, industrial electric fan heaters are all about cost effectiveness and versatility.

The Tiger range of electric fans heaters, for example, has ratings between 2 kW and 30 kW, each with on board thermostat control. The fans are ideal for use wherever temporary but effective heating is required, such as on building sites, in warehouses, workshops, shops, exhibition halls, assembly halls and garages. You can even attach them to a wall.

LPHW Heaters

Low pressure hot water (LPHW) is a flexible means of distributing heat to various zones or parts of a building. In a commercial or industrial setting, LPHW fan heaters or LPHW radiant panels are used and can be easily connected to the piped infrastructure. A piped LPHW system is a long-term investment - part of the building. The heat source (boiler, heat pump etc. ) and indeed the heat emitters (fan heaters, radiators, radiant panels etc) are easily changed and upgraded from time to time, when required.

LPHW Fan Heaters

Where heat is available in this form then the use of LPHW unit heaters fed on hot water is invariably the most cost-effective and indeed versatile method of space heating a room or building. LPHW is ideal for all commercial and industrial applications: retail outlets; leisure centres; exhibition halls; warehouses; factories; garages; workshops; plant rooms.

LPHW Radiant Panel Heating

Ceiling recessed LPHW radiant panels

Heating industrial workplaces with LPHW can also be delivered in the form of ceiling mounted LPHW radiant panels. They create a clean look and come in various sizes to suit a variety of commercial and industrial workplaces. They can be fitted within a suspended ceiling grid or suspended from a solid ceiling. The effect is that the heater blends to be part of the ceiling and it is very clean and neat. No surprise that this variety of radiant panel heaters are popular in schools, municipal buildings, and commercial spaces.

Suspended LPHW ceiling panels are seen when the ceiling is the roof line and particularly where the roof itself is a feature of the building, these radiant panels can add to the effect. Without the constraints of a ceiling grid they are available with a wider array of widths and again come in various lengths. All ranges have a system of jointing that ensures that panels can be combined to form a seamless run. These type of heaters are normally used in larger rooms such as sports halls and assembly rooms, and often feature ball covers to prevent balls getting caught on the top of the heater. This type of heater is also becoming increasingly common in 'clean' manufacturing settings.

Steam Heaters

Steam, which is often viewed as a means of powering the industrial past, is in fact still a feature of some of the larger industrial buildings. Where there is a steam infrastructure there are two heating options - fan heaters and radiant panels.

Steam fan heaters

Thermolier fan heaters are an industrial heating stalwart and are widely used on steam applications. Efficient heat transfer from steam to air and strategic placement of the heaters gives exceptionally fast warm up and practical heat control in large spaces. Requiring little or no maintenance, these heaters are tough and efficient, and are typically hung from the roof structure of from wall mounting brackets. There are vertical airflow versions available which are suited for mounting in the mid area of large buildings away from walls, where they can provide destratification as well as heating.

Steam Radiant Panels

Steam radiant panels are a niche line but can be useful in providing heat in zoned areas where the expense of putting electrical ATEX certified equipment is prohibitive. Depending on the heat requirement and steam pressure available in the pipework, we can work out the most cost-effective sizes and array of steam radiant heaters to deliver that requirement.Visit the Puravent website for more information on Heating Industrial Workplaces