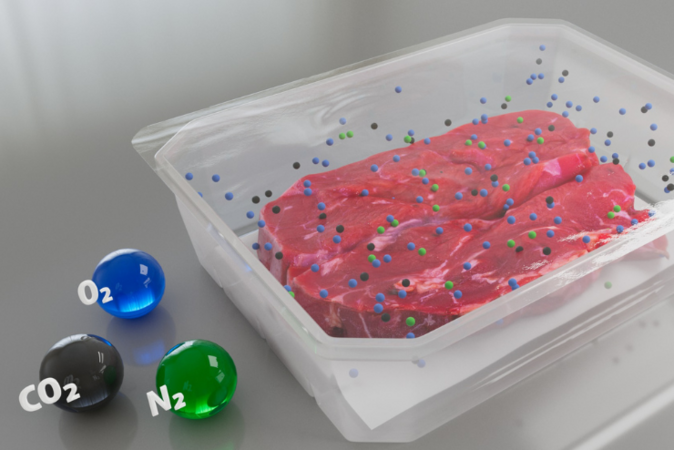

Suitable for oxygen - Taking Gas filters into a new dimension

01-06-2023

Visit the WITT Gas Techniques Ltd website for more information on Suitable for oxygen - Taking Gas filters into a new dimension