Connecting Safely in Extreme Environments

Transferring fuels, cryogenic liquids or aggressive chemicals is never straightforward. High pressures, extreme temperatures and hazardous media all present safety and operational challenges. Choosing the right couplings is vital to prevent leaks, protect personnel, and maintain efficient operations. EWFM’s range of couplings for extreme environments is designed to deliver secure, reliable connections in even the toughest conditions, ensuring peace of mind for operators across multiple industries.

Every application has unique demands, from temperature extremes to chemical aggressiveness. A coupling that performs perfectly in one scenario may fail in another, potentially causing downtime or hazardous incidents. That’s why understanding the environment and selecting the correct connection technology is essential for safe, efficient fluid transfer.

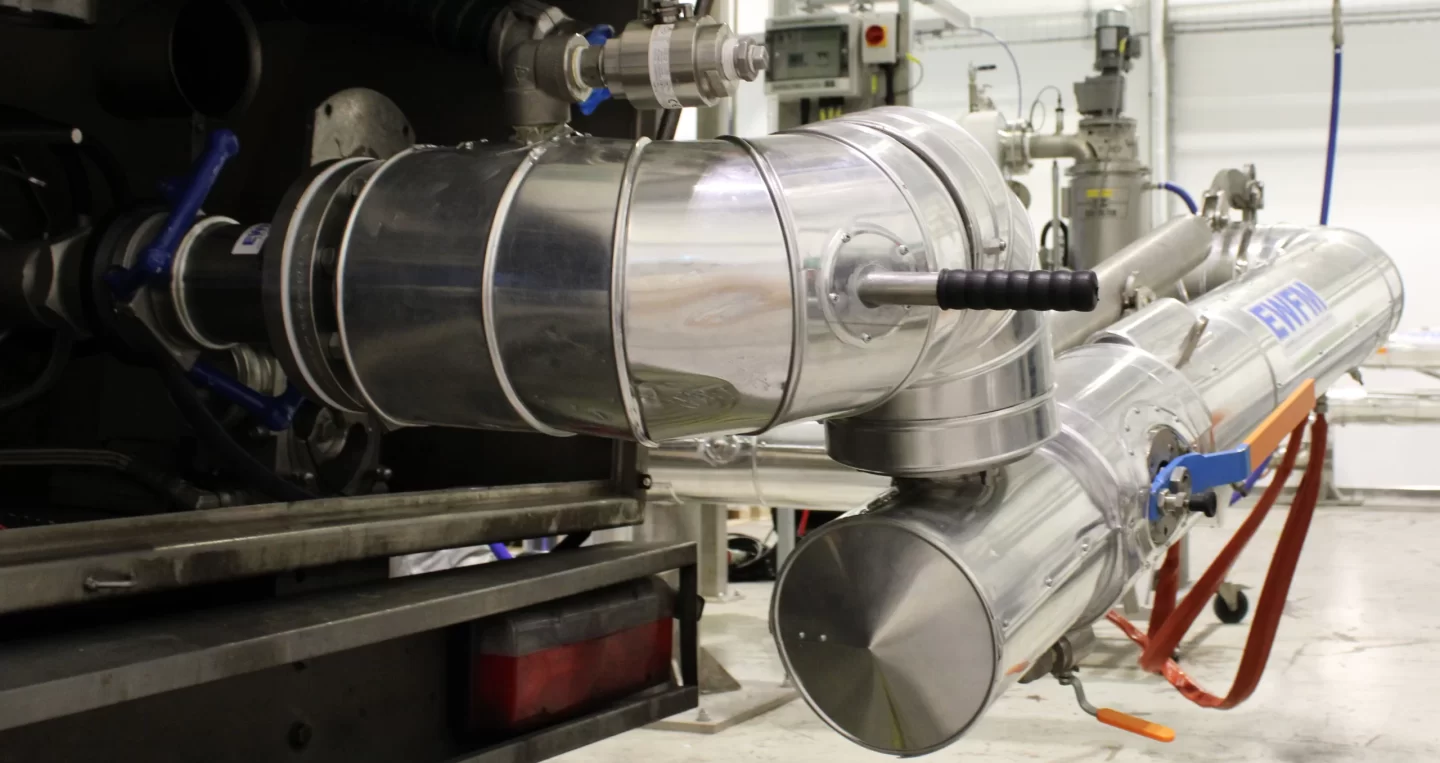

Couplings for Cryogenic Transfers:

Cryogenic liquids, such as liquid nitrogen, LNG and oxygen, require couplings that remain reliable at extremely low temperatures. Materials can contract and seals may become brittle, so high-spec construction and advanced sealing technology are critical. EWFM cryogenic couplings are designed to maintain a secure, leak-free connection, ensuring safe operation during tank loading, bunkering and other low-temperature transfers.

In addition to durability, operational simplicity is important. Features such as self-sealing valves and easy connection mechanisms minimise the risk of spills during use, protecting operators and the surrounding environment. By combining robust materials with functional design, cryogenic couplings provide reliable performance under challenging conditions while reducing maintenance requirements.

Couplings for Aviation Fuel Handling:

Aviation fuel operations require couplings that ensure quick and secure connections while minimising fuel loss. Dry aviation couplings are specifically designed to meet these needs, offering reliable performance in various aviation fuel logistics applications. These couplings are suitable for connecting hoses and loading arms to mobile and stationary tanks, tank trucks, and dispenser vehicles, both under pressure and with minimised liquid loss.

Constructed from materials like aluminium and stainless steel, dry aviation couplings are built to withstand the rigours of aviation fuel handling. They feature seals made from FKM, NBR, and low-temperature materials to ensure a secure seal under varying conditions. With a working pressure of up to 10 bars, these couplings are available with threaded and flanged connections for both hose and tank units. It’s important to note that they are not approved for underwing refuelling applications.

Couplings for Chemical Transfers:

Chemical plants handle a wide range of liquids, from corrosive acids to volatile solvents, each requiring compatible materials and precise sealing. Dry Disconnect Couplings (DDCs) are designed to meet these demands, offering secure, leak-free connections during the transfer of hazardous chemicals. These couplings are constructed from materials such as Hastelloy, stainless steel, and PEEK, ensuring compatibility with various chemical products. Seals made from Chemraz®, Kalrez®, and other perfluoroelastomers provide excellent chemical resistance, even in aggressive environments.

DDCs are engineered to prevent spills and product loss during connection and disconnection processes. They feature a self-sealing design that minimizes operator exposure and environmental impact. Available in sizes ranging from 1″ to 8″, with threaded and flanged connections, these couplings are suitable for use in industrial process plants, road and rail tankers, IBC containers, and pharmaceutical and petrochemical industries. Their robust construction and advanced sealing materials ensure reliable performance, enhancing safety and efficiency in chemical transfer operations.

Whether handling cryogenic liquids, aviation fuel or hazardous chemicals, selecting the right coupling is essential for safety and operational efficiency. EWFM’s couplings for extreme environments combine durable materials, reliable seals and practical safety features to ensure secure, leak-free connections in even the harshest conditions. Contact our team to discuss your application or find the ideal coupling solution for your operation.

Visit the EWFM website for more information on Connecting Safely in Extreme Environments